NB: Orders will not be processed from December 19th to January 5th due to ERP implementation. Order well in advance!

language

Worldwide Express Shipping

local_shipping

Urgent delivery possible

shield

NEN-EN-ISO 9001 certified

quick_reorder

Shipped the same day

language

Worldwide Express Shipping

local_shipping

Urgent delivery possible

shield

NEN-EN-ISO 9001 certified

quick_reorder

Shipped the same day

menu

discover_tune

/

and VAT settings

person

Log in

My account

Belt technology

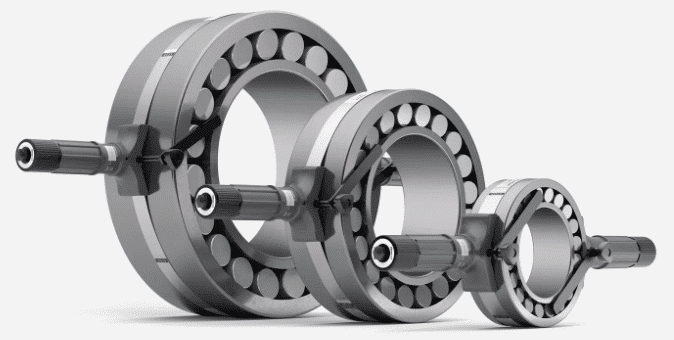

Bearing technology

Chain technology

Coupling technology

Customer Service

Product info

Contact

discover_tune

/

en btw instellingen

Receive

10% off!

Thank you!

On your first order

Your discount is on its way

Join over 10,000 happy customersReceive

10% off!

One more step to go

- Get 10% off your first order instantly

- Enjoy faster and easier checkout

- Be the first to know about new deals and promotions