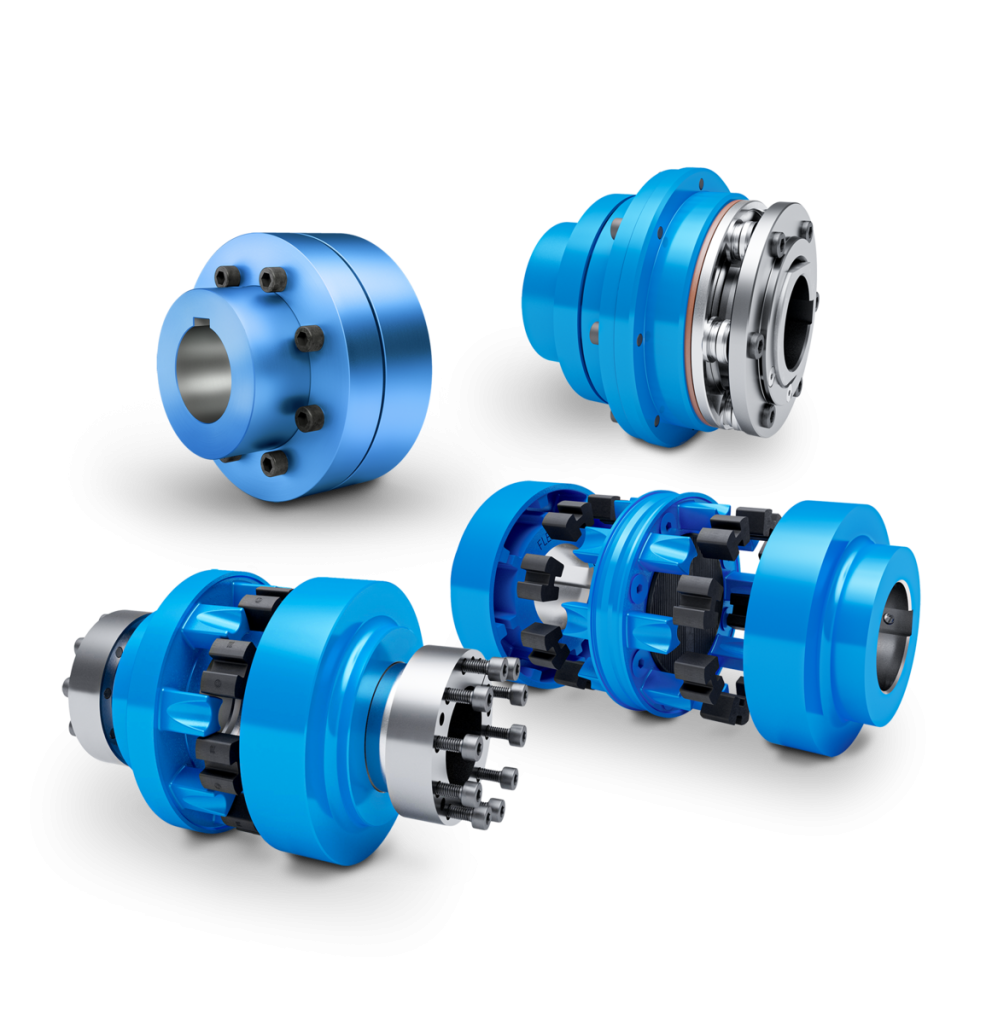

Optimum power transmission with FLENDER shaft couplings

In the world of drive technology, the shaft coupling is a crucial component for reliable machinery. FLENDER shaft couplings are recognized and used worldwide by both OEMs and end users for their high quality and versatility. Whether it's torque capacity, misalignment compensation, or torsional damping, FLENDER's product families offer a suitable solution for every challenge.

Flender has a solution for every application

The strength of the FLENDER range lies in the diversity of its series, each designed for specific industrial needs:

- N-EUPEX: This is the standard torsionally flexible motor-pump/fan coupling. This series is known for its robustness, low maintenance, and tolerance to misalignment, making it the ideal choice for general pump drives and conveyors.

- RUPEX: For environments with higher shock loads, such as mills and crushers, the RUPEX series provides the necessary additional damping and compensation for misalignment. These couplings are also ideal for heavy-duty starts and variable-frequency drives.

- ARPEX: When machines run at high speeds or require a torsionally rigid connection, this steel multi-disc coupling is the ideal option. They are frequently used in critical applications in the chemical and oil & gas industries.

- ELPEX / ELPEX-B: These series have been specifically developed for installations with highly irregular torsion or high vibration levels, such as with pulsating pumps.

- ZAPEX: For situations where very high torques are required in a compact design, this ring gear coupling offers the solution, often in combination with gearboxes.

Flender's application areas and innovations

The shaft couplings from FLENDER They prove their value in a wide range of sectors. In the energy sector, they are used for cooling water pumps and flue gas fans, while in the chemical and offshore industries, they are essential for process compressors and winches. These couplings are also a proven asset in water treatment (aerators and sewage pumping stations) and the rail and maritime sectors (train drivelines and ballast pumps).

Modern installations also require smart solutions. FLENDER responds to the need for predictive maintenance with technologies like "AIQ Detect," further increasing the reliability of your machinery.

Selecting the right coupling is a specialist's job. Spruit Drive Technology not only supports you with delivery but also assists with the complete selection and sizing of the right FLENDER shaft coupling for your specific application. This ensures a long service life and maximum ease of maintenance for your drive.