Electrification in drive technology: the transition to sustainable drives

The industrial world is on the cusp of a revolution. The electrification of drive technology is no longer a vision of the future, but a rapidly unfolding reality. From production chains to mobile equipment, we are seeing a shift from conventional drives to electric systems everywhere. This transformation offers unprecedented opportunities for efficiency, sustainability, and innovation.

Why electrification is now becoming the standard.

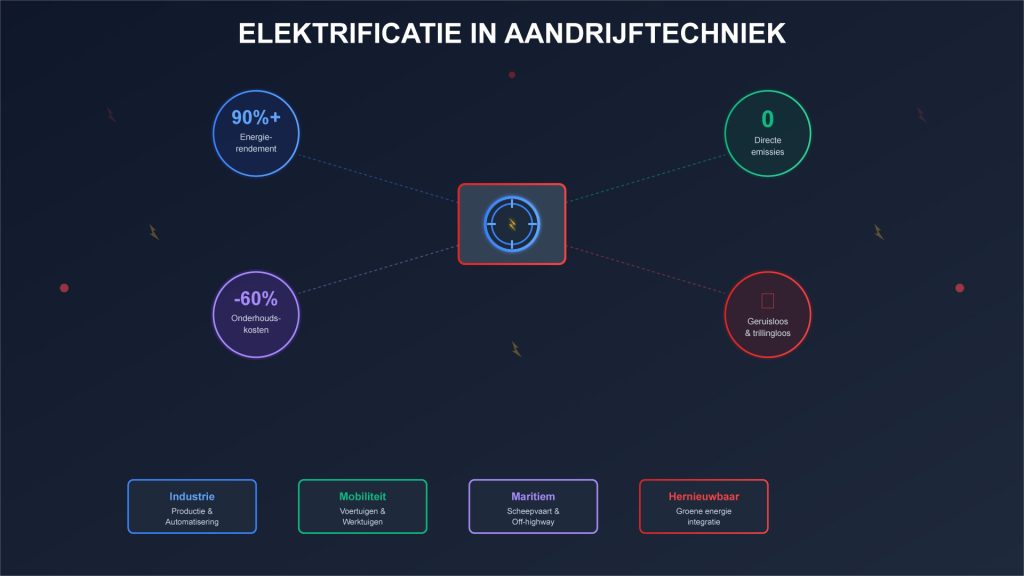

The drivers behind electrification are multifaceted and compelling. Stricter emissions standards and climate targets are forcing companies to seek alternatives to fossil fuels. At the same time, technological breakthroughs in battery systems, power electronics, and electric motors are making this transition increasingly attractive from an economic perspective. Electric drive systems offer significant energy efficiency benefits. While combustion engines convert an average of 30-40% of the fuel's energy into useful work, electric motors achieve efficiencies of 90% or higher. This directly translates into lower operating costs and a smaller ecological footprint.

Fields of application in practice: Industrial automation

In production facilities, electric servo motors and variable frequency drives are the backbone of modern automation. These systems offer precise positioning, high dynamics, and excellent controllability. The result: higher production quality, shorter cycle times, and predictable maintenance.

Mobile equipment

From forklifts to construction machinery, electrification is permeating the mobile equipment sector. Lithium-ion technology enables fully electric operation with zero on-site emissions. This represents a breakthrough for health and safety, especially in inner-city environments and indoor spaces.

Maritime and off-highway applications

Electrification is also gaining ground in heavier sectors like shipping and mining. Hybrid systems combine the best of both worlds: the flexibility of conventional drivetrains with the efficiency of electric systems during peak demand or idling.

The concrete benefits of electrification.

Operational efficiency and cost savings. The most immediate benefit of electric drive systems is the dramatic improvement in energy efficiency. Electric motors convert more than 90% of electrical energy into mechanical energy, compared to 30% to 40% of combustion engines. This efficiency gain translates directly into lower energy costs, which can increase significantly over the life of a system.

Maintenance costs also decrease dramatically. Electric drives require no oil changes, fuel filters, spark plugs, or exhaust systems. The number of moving parts is minimal, which reduces wear and increases reliability. Practical examples show that maintenance costs can be reduced with the 40-60% compared to conventional systems.

Emission-free and sustainable

Electric drives produce no direct emissions of CO₂, nitrogen oxides (NOx), or particulate matter. In inner-city areas and enclosed spaces, this means a revolution for air quality and working conditions. Employees in warehouses and production halls are no longer exposed to harmful exhaust fumes.

When electrical systems are powered by renewable energy, the entire operational chain is virtually emission-free. Even when using the conventional electricity grid, well-to-wheel emissions are significantly lower than with fossil fuels, and this ratio improves as the share of renewable energy in the grid increases.

Performance and ease of use

Electric motors deliver maximum torque instantly from a standstill. This characteristic results in superior acceleration and responsiveness, which is a major advantage, especially in dynamic applications. Operators experience immediate and precise responses to control commands, which improves productivity and safety.

The noise level of electric drives is significantly lower than that of combustion engines. This is a decisive factor in city centers, residential areas, and noise-sensitive environments such as hospitals or educational institutions. Vibrations are also significantly reduced, which extends the lifespan of structures and loads.

Pprecision and controllability

Modern electric drive systems offer unprecedented possibilities for precise speed and position control. Variable-speed drives can continuously adjust the speed to meet process requirements, saving energy and improving product quality. In automation applications, servo motors achieve positioning accuracies of a few micrometers.

This controllability also enables regenerative braking. When decelerating or descending, kinetic energy is recovered and stored in batteries or fed back into the grid. In applications with frequent start-stop cycles or elevation changes, this can lead to energy savings of 15-30%.

Future-proofing and compliance

Investing in electrification means anticipating future regulations. Emission zones in cities are becoming increasingly strict, and tenders increasingly include sustainability requirements. Electric drive systems already meet the strictest standards likely to be implemented in the coming decades.

In addition, electrification strengthens organizations' image. Sustainable business practices are becoming increasingly important for customers, investors, and employees. Concrete steps toward emission reduction contribute to social acceptance and can even provide a competitive advantage in tenders and procurement processes.

Flexibility in energy supply

Electrical systems can be powered by various sources: the grid, solar panels, wind energy, or backup generators. This flexibility makes companies less dependent on fossil fuels and their price fluctuations. During peak energy prices, battery systems can act as a buffer, allowing charging to take place during low-price periods.

In remote locations or off-grid situations, hybrid systems can be deployed, where a small generator runs only when needed, while most of the work is done electrically. This combines the autonomy of conventional systems with the advantages of electric propulsion.

Technological building blocks; Electric motors: the beating heart

Modern electric motors come in various designs, each with specific characteristics. Permanent magnet technology dominates where high power and compact design are crucial. Induction motors remain the preferred choice in rugged industrial environments due to their reliability and low-maintenance properties.

Power electronics and controls

Advanced frequency converters and inverters ensure optimal control of electric motors. These systems dynamically adjust voltage and frequency, allowing precise control of speed and torque. Modern control algorithms not only optimize performance but also minimize energy loss.

Energy storage: the enabler of mobility

Battery systems largely determine the feasibility of mobile electrification. The energy density of lithium-ion technology has doubled in recent years, while costs have dropped by more than 80%. Solid-state batteries and other innovations promise further improvements in safety, charging speed, and durability.

Challenges and solutions

Grid load and charging infrastructure. The massive introduction of electric systems is putting pressure on existing electricity grids. Smart charging strategies, where charging is spread out over off-peak hours, help manage this load. Local energy storage and decentralized energy generation via solar panels offer additional solutions.

Initial investment costs

Although operating costs are lower, electric drive systems often require a higher initial investment. Total Cost of Ownership (TCO) analyses, however, show that the payback period is getting shorter, often between three and five years. Subsidy programs and tax incentives further accelerate this process.

Knowledge and skills

The transition to electrification demands new skills from technical personnel. Understanding power electronics, battery management, and electrical safety is essential. Therefore, investments in education and training are inextricably linked to successful implementation.

The future: smarter and integrated

Electrification is just the beginning. The next step is integration with digital technologies. Smart drive systems communicate with each other and with central management systems, enabling predictive maintenance and real-time optimization. Artificial intelligence analyzes usage patterns and autonomously adjusts parameters for maximum efficiency.

The connection with renewable energy sources closes the loop. Electric systems can function as temporary energy storage, feeding electricity back into the grid during peak hours. These vehicle-to-grid and machine-to-grid concepts transform drive systems from consumers into active participants in the energy system.

Conclusion: an irreversible movement

Electrification in drive technology isn't a trend, but a fundamental shift that will permanently transform the industry. The combination of regulations, technological advancements, and economic benefits makes this transition irreversible. Companies investing in electric drive systems now are positioning themselves as pioneers in a sustainable and efficient future.

The challenge is no longer whether we should electrify, but how we can best achieve this within specific applications and operational contexts. With the right knowledge, planning, and partner selection, electrification offers a concrete path to future-proof business operations.