Bearing lubrication: the key to maximum service life

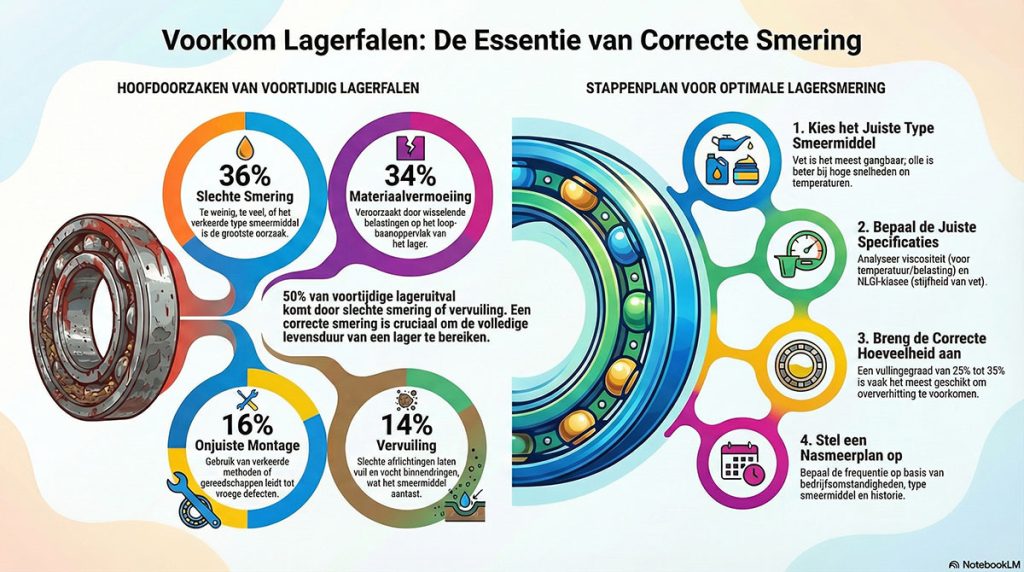

Proper lubrication is the most crucial step in achieving the full service life of a bearing. More than half (50% to 60%) of all premature bearing failures are caused by poor lubrication or contamination. By reducing friction, wear, and corrosion, the right lubricant ensures reliable operation, lower maintenance costs, and extended equipment life.

Grease, oil or coating: the basic choice

This can be roughly divided into lubrication with grease, lubrication with oil, or, in the case of plain bearings, a coating.

Grease lubrication

This is the most commonly used method, applied to approximately 80% rolling bearings. Grease consists of base oil, thickener, and additives. Its advantages include simple lubrication, reduced leakage, and a sealing effect that prevents the ingress of dust and moisture. A disadvantage is that heat dissipation is less effective, resulting in a relatively low permissible speed (DN value).

Oil lubricantg

This is the ideal solution for applications under extreme conditions, such as high speeds and high temperatures. Circulating lubricating oil can effectively dissipate internal frictional heat, which can have a cooling effect. This is often used in gearboxes and sometimes bearing housings and couplings.

PTFE coating

Plain bearings with a PTFE coating are pre-lubricated by the manufacturer and are generally low-maintenance, making relubrication unnecessary.

The right choice of lubricant

Selecting the right lubricant is a complex process based on operating conditions and manufacturer requirements.

Viscosity and speed

The viscosity of the base oil is a decisive characteristic.

- High Speed: Requires a lower viscosity because this creates less internal friction and dissipates heat better, helping to prevent overheating.

- Heavy Load: Requires a higher viscosity because it forms a thicker lubricating film and dampens heavy loads.

The DN factor (bearing diameter in millimeters multiplied by the speed in revolutions per minute) provides an essential indication of the bearing's load and speed, which aids in selection.

Consistency (NLGI grade)

The National Lubricating Grease Institute (NLGI) grade determines the consistency or stiffness of the grease. This classification ranges from fluid (NLGI 000) to very firm (NLGI 6). Standard greases often fall into NLGI grade 2. Firmer greases (higher NLGI numbers) are a good choice if leakage is a concern and heavy loads are encountered.

Temperature

When selecting a bearing based on operating temperature, the dropping point and oxidation stability are crucial. Ideally, the actual operating temperature of the bearing should be 10 to 20 degrees Celsius below the grease's dropping point. High temperatures accelerate grease oxidation, shortening its service life.

The crucial factor: quantity

Besides choosing the right lubricant, the quantity is crucial. Too much grease is harmful. Overfilling causes increased friction torque and a linear increase in bearing temperature. This can accelerate oxidation, damage seals, and even lead to premature failure.

The recommended fill level is usually specified by the manufacturer, often between 20% and 40% of the free internal space. For ball bearings, 25% to 35% grease is often considered most suitable.

Lubrication methods and planning

A good relubrication plan, based on operating conditions and lubricant characteristics, is necessary. Bearings Can be lubricated manually, for example, with a battery-powered grease gun, where accurate dosing is crucial to prevent over- or under-lubrication. However, automatic lubrication systems are increasingly being used. These systems ensure a continuous, consistent, and contamination-free grease supply, increasing machine reliability.