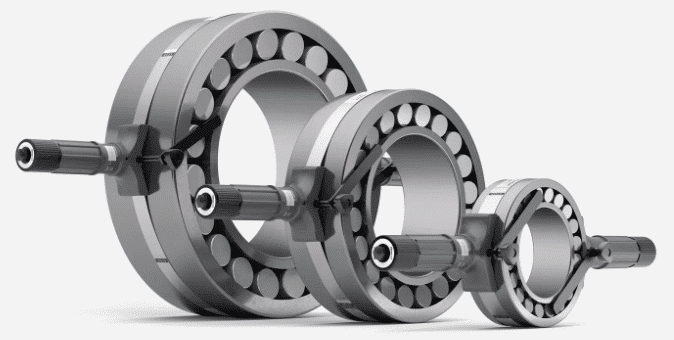

Axial and radial ball bearings: the differences.

Bearings are crucial components in all kinds of machines and vehicles, and they play an important role in supporting rotation and movement. There are several types, but two of the most common are radial and axial bearings. Although both types of bearings are used to support rotation, they have different applications and properties that make them suitable for specific types of loads.

Radial bearings

Radial models are designed to absorb forces that work perpendicular to the axis of rotation. This means that they are primarily used to support radial loads. Radial bearings are often found in applications such as wheels, engines, and other rotating machinery where the load is primarily in a radial direction. These types are essential for the smooth and efficient running of these machines and vehicles.

One of the most common types of radial bearings are ball bearings and roller bearings. Ball bearings use small balls to reduce friction between moving parts, while roller bearings use cylindrical rollers. Both types are capable of high speeds and low to medium loads, making them ideal for applications where fast rotation and relatively light loads are required.

Additional information via the website of Spruit Drive Technology.

Applications of radial bearings:

- Wheels of cars and bicycles: Radial bearings ensure that the wheels turn smoothly and the forces acting perpendicular to the axle are supported.

- Engines: In engines, radial bearings help support the rotating parts and ensure efficient operation.

- Rotating machines such as fans: Radial bearings ensure that the fan blades rotate smoothly and the radial forces are absorbed.

Axial bearings

Axial bearings, also called thrust bearings, are designed to absorb forces acting along the axis of rotation. This means that they are primarily used to support axial loads. Axial designs are often used in applications such as screw shafts, rotary platforms and other machines where the load is primarily in an axial direction. These bearings are essential for supporting the vertical or horizontal forces acting along the axis.

Common types of axial bearings are axial ball bearings and axial roller bearings. Axial ball bearings use small balls to reduce friction between moving parts, while axial roller bearings use cylindrical rollers. Both types are suitable for low to medium speeds and high axial loads, making them ideal for applications requiring slow rotation and heavy axial loads.

Applications of Axial Bearings:

- Ship propeller shafts: Axial bearings support the forces acting along the axis of the propeller shaft, allowing the propeller to rotate efficiently.

- Rotary Platforms: In rotary platforms, axial bearings help support the vertical forces acting along the axis, allowing the platform to rotate smoothly.

- Machines with vertical axes such as drilling machines: Axial bearings ensure that the drill rotates smoothly and the axial forces are absorbed.

Summary

Both are essential for the smooth and efficient running of various machines and vehicles, but they have different applications and properties. Radial versions support forces acting perpendicular to the axis and are used in wheels, motors and fans. Thrust bearings support forces acting along the axis and are used in propeller shafts, rotary platforms and drilling machines.

Due to their specific design and properties, radial and axial bearings are able to support the right types of loads, making them indispensable in a wide range of applications. Understanding the differences between these two types of bearings helps in selecting the right bearing for a specific application, which is essential for the optimal operation and lifespan of machines and vehicles.