Drive by belts, V-belts and chains

Drive systems play a vital role in various industries, from automotive to industrial machinery. They transfer energy from the power source to the driven components. Various types of drive systems are available, including V-belts, belts, chains, and couplings. Each type has its own unique properties and applications.

V-belts and their applications

V-belts are a commonly used type of drive system Characterized by their V-shaped profile, they are often used in applications requiring flexibility and simplicity, such as fans, pumps, and small machinery. V-belts operate by friction between the belt and pulleys, which transmits energy. They offer several advantages, including easy installation, low cost, and a wide range of sizes and designs.

However, the use of V-belts also has some disadvantages. They have limited power capacities and are susceptible to wear and slippage. Therefore, they may not be suitable for heavy-duty industrial applications requiring high power.

Belt Drives: Types and Considerations

Belt drives are another common type of drive system. They consist of a belt running over pulleys to transmit power. Belt drives can be flat or toothed belts, depending on the application and requirements. They are often used in industrial machinery, such as conveyors, fans, and compressors.

Belt drives offer several advantages, including higher power output, improved grip, and reduced wear. However, they are prone to deformation and may require regular maintenance to maintain optimal performance.

Comparison of V-belts, belts and chains

Choosing the right solution for your specific needs can be a challenging task. To make the right decision, it's important to understand the pros and cons of each type and compare them to your specific requirements.

V-belts are ideal for applications requiring flexibility and simplicity, but they have limited power capacities. Belt drives offer higher power capacities but may require regular maintenance. Chain drives offer high power capacities and reliability, but require regular lubrication.

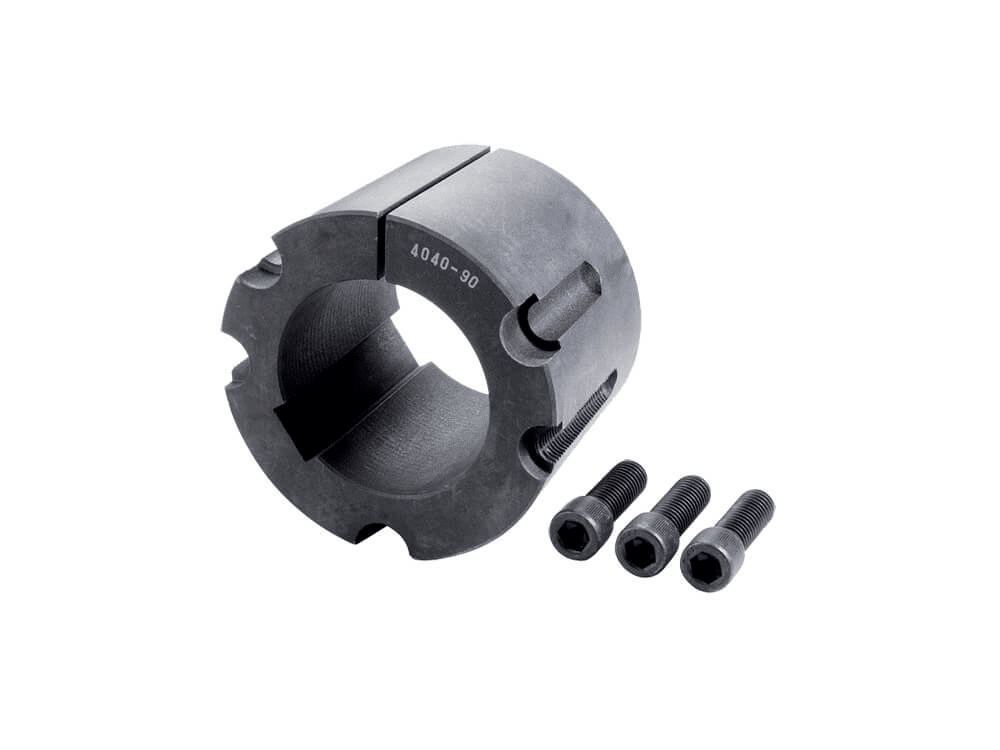

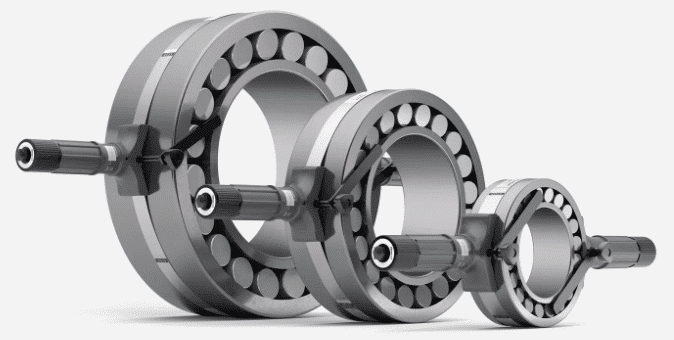

Couplings in drive systems

Links play a crucial role in drive systems by enabling the transfer of energy between different components. They are used to connect two shafts and transmit the energy. Various types of couplings are available, including toothed couplings, flexible couplings, and magnetic couplings. The choice of the right coupling depends on factors such as power requirements, alignment, and vibration damping.

When choosing a drive system, there are several factors to consider. Some important considerations include power requirements, application, environmental conditions, maintenance requirements, and budget. By carefully evaluating these factors, you can select the right drive system for your specific needs.

General applications of various drive systems

V-belts, beltsChains, and couplings are used in various industries and applications. V-belts are often used in fans, pumps, compressors, and small machinery. Belt drives are used in conveyors, fans, compressors, and industrial machinery. Chain drives are used in motorcycles, bicycles, conveyors, and industrial machinery. Couplings are used in all kinds of drive systems, from automotive to industrial machinery.

Drive systems are crucial to the operation of various machines and equipment across different industries. Understanding the characteristics and applications of V-belts, belt drives, chain drives, and couplings helps make informed choices for specific needs. By considering factors such as power requirements, maintenance, and budget, the right drive system can be selected to ensure optimal performance and reliability.

At Aandrijftechniek.nl, located in the vibrant city of Alkmaar and operating throughout the Benelux, we invite you to explore the fascinating world of industrial drive technology with us. Our passionate team of experts is ready to help you gain a deep understanding of our commitment to high-quality drive solutions.

How do you make the right choice for replacement components that deliver top performance for your drive system? How do you calculate service life and anticipate maintenance costs? Which groundbreaking innovations in drive technology can optimize the efficiency of your production process? None question is too complex For our enthusiastic specialists. At Aandrijftechniek.nl, we combine our expertise and drive to tackle the most challenging issues in industrial drive technology.

We sell the above products through our webshop, including: Megadyne, Gates, Protorgue, Continental and IWIS.