Plain bearings from Schaeffler – maintenance-free

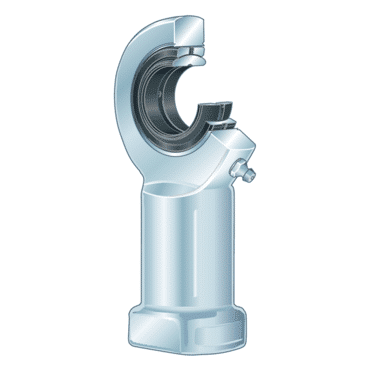

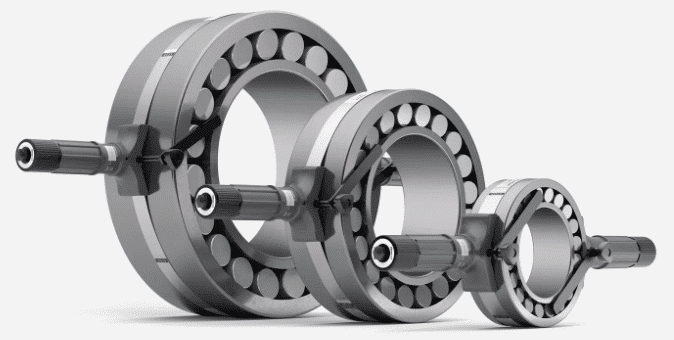

A plain bearing, also known as a bushing, is a type of bearing that allows movement between two surfaces by sliding instead of rolling. Unlike roller bearings, which use rotating elements such as balls or rollers, plain bearings operate by direct contact between moving parts. This type of bearing is often used in applications where low speed, high loads, and long life are required.

Plain bearings and their applications

These types of bearings are used in a wide range of applications, ranging from industrial machinery to consumer products. Some common applications include:

- Automotive Industry: Plain bearings are used in various parts of vehicles such as suspension, steering and engine components. They provide reliable performance under heavy loads and high temperatures.

- Aerospace: Plain bearings are used in aircraft and spacecraft for their ability to withstand extreme temperatures and loads. They are often used in moving parts of wings, landing gear and engines.

- Mechanical Engineering: Industrial machinery such as presses, pumps and turbines use plain bearings for their durability and ability to carry heavy loads. They are essential for the smooth operation of these machines.

- Consumer Products: Plain bearings are also used in everyday products such as household appliances, sports equipment and electronics. They ensure quiet and smooth operation of moving parts.

The advantages of this type of bearings

Plain bearings offer several advantages over other types of bearings, such as roller bearings. Some of the main advantages are:

- Maintenance-free: Many plain bearings are designed to be maintenance-free. This means that they do not require regular lubrication, which significantly reduces maintenance costs. Innovative materials such as PTFE (polytetrafluoroethylene) ensure low friction and minimal wear, which extends the life of the bearing.

- Environmentally friendly: Because these bearings often do not require oil or grease, they are more environmentally friendly than bearings that require regular lubrication. This reduces the amount of harmful substances that end up in the environment.

- Low friction: They have a low coefficient of friction, which means they use less energy when moving. This makes them more efficient and helps reduce energy consumption in machines and devices.

- High load capacity: These bearings can carry heavy loads without deforming or failing. This makes them ideal for applications where high pressure and stress are involved, such as in industrial machinery and vehicles.

- Quiet operation: Because plain bearings have no moving parts such as balls or rollers, they are often quieter in operation. This is a significant advantage in applications where noise can be a problem, such as in household appliances and electronics.

- Simple construction: Plain bearings have a simple construction without complex moving parts. This makes them easier to manufacture and install, which reduces costs and increases reliability.

Plain bearings are an essential component of many machines and devices, and offer numerous advantages such as freedom from maintenance, environmental friendliness, low friction, high load capacity, quiet operation and simple construction. Thanks to innovative materials such as ELGOGLIDE, ELGOTEX and E40, plain bearings remain a reliable and efficient solution for a wide range of applications. Whether in the automotive industry, aerospace, mechanical engineering or consumer products, plain bearings play a crucial role in improving the performance and durability of moving parts.

Schaeffler bearings

Schaeffler offers a comprehensive catalogue of maintenance-free plain bearings. These bearings are made of innovative materials such as ELGOGLIDE, ELGOTEX and the metal-polymer composite material E40. Due to the PTFE basis of these materials, they have a very low friction value and minimal weare, which ensures a long service life. These plain bearings are ideal for spherical plain bearings, rod ends, bushings, discs and strips. Because they do not require oil or grease, they significantly reduce lubrication and maintenance costs and are also very environmentally friendly.

Want to know more about this product or ask a question? Then use our contact form.